Lean manufacturing also considered as Lean production is a tool/methodology to eliminate waste from the manufacturing unit to improve efficiency and profitability. The lean approach thoroughly analysis the each process of Supply chain management to eliminate “Muda”, a Japanese word for waste. James Womack’s first mentioned the concept of Lean manufacturing in his 1990′ book, “The Machine That Changed the World“. The Lean management key focus is on “Value for Money” from Customer perspective i.e. simple means “Is it worth?”

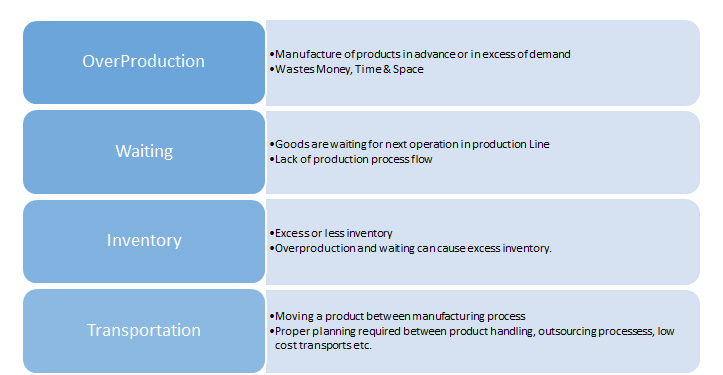

The 7 “Muda” by Toyota Production system(TPM)

Push-Pull Strategy

Pull-Push strategies often involves in analyzing the approaches to supply chain management in manufacturing . In simple, Suppliers “push” products to their customers by marketing; customers “pull” products from suppliers by placing orders. Both are defined to eliminate waste in the production process.

Push Strategy

“Push type” means “make-to-stock,” in which the production is not based on actual demand. For example, the push system of inventory control involves forecasting inventory needs to meet customer demand. But the customer demand is purely based on forecasting with different factor driving the demand.

An example for approach of a push system is Materials Requirements Planning, or MRP. MRP combines the calculations for financial, operations and logistics planning. It is a tool which controls scheduling and ordering. Its purpose is to make sure raw goods and materials needed for production are available when they are needed.

Pull strategy

“Pull type” means “make-to-order,” in which the production is based on actual demand. The goal of a pull-based lean manufacturing environment is to make nothing until there is demand. Finished goods are not produced without a specific customer order. One advantage to the system is that there will be no excess of inventory that needs to be stored, thus reducing inventory levels and the cost of carrying and storing goods.

The JIT, Just in Time management can be considered as Pan example of Pull strategy. The JIT system eliminates waste by reducing the amount of storage space needed for inventory and the costs of storing goods.

Different Between Push-Pull strategy

Conclusion

Push and pull models of manufacturing are two major approaches implemented by organizations. The decision on which approach to use is often based on their business strategy. Push and pull-based models in manufacturing starts at the planning phase and continues through the execution stage. Companies now focus on hybrid model which includes both Pull-Push system for production .

© 2026 NIQC International. All rights reserved.